Floor drains are an essential component of any commercial or industrial facility that handles liquids or waste. However, despite its critical role, it’s often overlooked or misunderstood. As a result, many business owners and facility managers may have questions about floor drainage systems and their functionality. We will answer the most frequently asked questions about floor drainage to help you better understand its importance and how to maintain it properly.

1. What is the purpose of floor drains?

Floor drains are designed to prevent water from pooling on the floor in areas where spills, leaks, or washdowns are likely to occur. Floor drains help to keep the floor dry and reduce the risk of slips and falls, as well as improve indoor air quality by reducing mold and mildew growth.

2. What materials are floor drains typically made of?

In general, floor drains are made from durable and rust-resistant materials that are easy to clean. These materials include stainless steel, cast iron, and plastic composites. At our company, we use T304 or T316 stainless steel to construct our FoodSafe Drains, Landscape Drains, and Slot Drains. This high-quality drainage system is not only efficient to clean, but it also enables quick and easy maintenance of a hygienic food processing facility.

3. How do I know what size floor drain I need for my facility?

Determining the appropriate size of a floor drain for your facility requires consideration of the size of the area that needs to be drained and the volume of water that will be flowing through it. Most often, A plumbing professional can assist you in selecting the appropriate drain size for your facility. Alternatively, our team of drainage experts are happy to help identify drainage issues and assist you in selecting the right drainage size and solution.

4. When should I be purchasing drains?

Drainage should be considered during the planning, which includes the design stage of any commercial or industrial facility that handles liquids or waste. It’s essential to assess the type of liquids or waste that will be present in the facility and determine the appropriate drainage system that will effectively manage it. Additionally, factors such as the facility’s layout, traffic flow, and accessibility should be taken into consideration when designing the drainage system. In conclusion, proper planning and consideration of drainage at the early stages of construction or renovation can save time, money, and potential safety issues in the long run.

5. How do I properly maintain my floor drains?

Floor drains require proper cleaning and maintenance, Global Drain Technologies prides itself and creating robust drains that require minimal maintenance and are easy to clean. Saving you time and money. Slot Drains have no grates that need to be removed or cleaned. Simply clean the drains with our cleaning brush and paddle. In addition, we have an innovative CIP feature designed for Slot Drain Systems®. This allows you to fill your drain with hot water and sanitizer to get a deep clean.

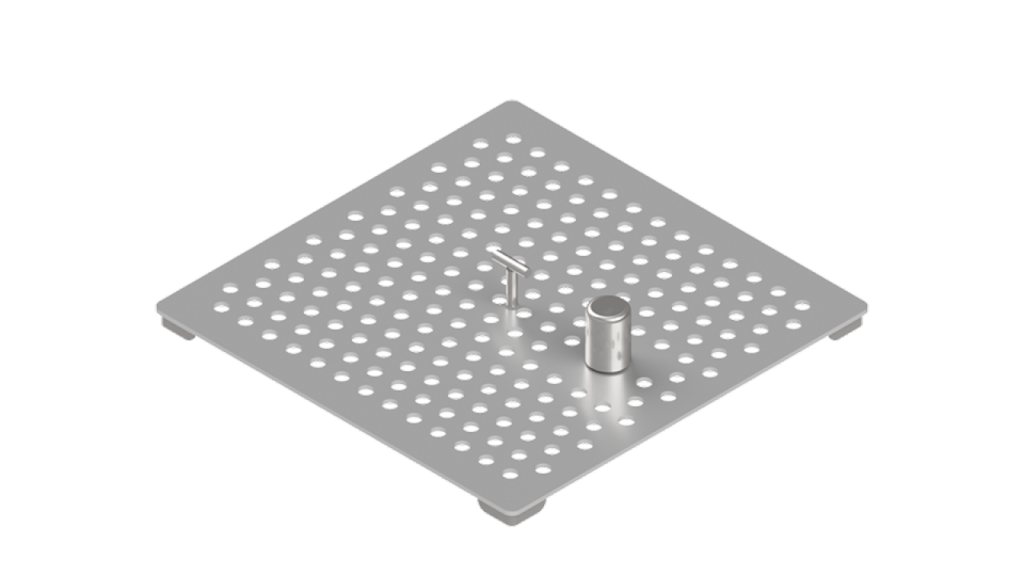

6. What type of strainer should I use with my floor drain?

Selecting the appropriate strainer for your floor drain is dependent on the type of drain you have and the intended application. We recommend using our strainer basket which is designed to be easily accessible and safely collect misplaced items until they can be retrieved. Our strainer basket is made from durable stainless steel for long-lasting use and fits perfectly in our catch basins.

7. Can floor drains be used in areas with forklift traffic?

Yes, floor drains can be used in areas with forklift traffic. Depending on the type of traffic in your facility, as well as the specific area, you’ll need a floor drain system that can handle the necessary loads without breaking, which can be costly to repair and create hazards for workers. Read more about load class ratings and which is right for your facility in our blog article.

8. What is the maximum load capacity of a floor drain?

The maximum load capacity of a floor drain depends on the load class rating of the drain. Load class ratings range from A (light duty) to F (extra heavy duty). Each class indicates the amount of weight the drain can handle without failing. In a food facility, a floor drain typically requires a load class rating of C or higher to support the weight of equipment and foot traffic. Reach out to our drainage experts to determine the appropriate load class rating for your specific facility needs. https://foodsafedrains.com/forms/contact-us

8. How do I prevent clogs in my floor drain?

Preventing clogs in a floor drain can be achieved by regularly cleaning the drain and strainer. The disposal of large or non-degradable items should be avoided. Check out our tamper-proof magnetic strainer, saving you from costly backups.

9. Can floor drains be retrofitted into an existing facility?

Yes, floor drains can be retrofitted into an existing facility. Our professional staff are available to provide suggested layouts for retrofit installation, as well as specification guidelines for tender purposes. Shop drawings are available upon receipt of purchase orders. Read more here.

10. What regulations exist for floor drain installation in processing facilities?

The regulations for floor drain installation in processing facilities can vary depending on the location and type of facility, but there are some common standards and codes that are often followed. Some of these include National Sanitation Foundation (NSF), Occupational Safety and Health Administration (OSHA) standards, International Plumbing Code (IPC), International Building Code (IBC) etc.

It is important to consult local regulations and codes, as well as industry-specific standards, to ensure that floor drain installations comply with all applicable requirements.

11. Who can install the Drains?

To install your drain system, we generally recommend hiring a plumber and concrete contractor to ensure that installation goes smoothly from start to finish. However, our drains have also been used in DIY projects numerous times by those with a good working knowledge of the principles involved in installing our drainage systems.