Automotive Shop Drains are a necessary but sometimes overlooked feature of a shop floor retrofit. We followed one of our customers, Glass Lab Auto Glass, to document the process of installing a shop drain and epoxy floor coating on an existing concrete slab. The following blog explores: parts, process and pricing, to help you make the right decisions for your automotive shop renovation.

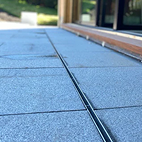

When designing their shop floor Glass Lab wanted to visually communicate the aesthetics, refinement, and attention to detail central to their brand. To do this Glass Lab chose high-end finishes including a fully stainless steel 6000 Plus Series Slot Drain System and an epoxy flake floor coating. When customers bring their cars for service at Glass Lab they see a shop that is clean, safe, and durable while at the same time sleek and modern.

Retrofitting a concrete slab with a new drain system and floor coating can make a floor more functional and durable, giving it new life. A proper drainage system combined with a durable floor coating will protect your concrete, decrease liability, and reduce cleanup time. Taking advantage of existing real estate can be a cost-effective way to expand your business but retrofitting does come with its own challenges. In this blog, we go over a basic list of parts needed to accomplish this task as well as some tips and tricks on pairing a Slot Drain System with an epoxy floor coating.

Parts List

A Slot Drain System is a long pre-sloped drain that has no sharp edges or tripping hazards. It can be driven over by cars and can easily accept fluids from the shop floor. It is also easy to clean. Using specialized brushes and paddles, staff can push any waste trapped in the slot drain towards the catch basin. Learn more about how a slot drain system compares to other drains.

A Catch Basin is the endpoint for a drain. It is the gatekeeper between the waste generated by your business and the public sewer system or private holding tank. There is a good chance that cars, trucks or other heavy equipment could drive across the catch basin so ensuring that you choose a catch basin that is rated for those types of weight loads is a must. Slot Drain catch basins have a T304 stainless steel lid and can be manufactured to various depths and weight ratings depending on your application. Catch basins should have some form of strainer in order to intercept solids before they reach your main drain pipe. This allows you to open the catch basin and remove debris (like glass or plastic) or lost items (like 10 mm sockets).

Epoxy Floor Coating is a durable and beautiful option for commercial spaces such as automotive shops. Using an epoxy floor coating after retrofitting an existing slab with a new drain system has the advantage of hiding the cuts that were made to the floor during installation. Glass Lab Auto Glass chose a flake finish and achieved a beautiful and functional result.

STOP safety first!

Installing your catch basins and associated drains will mean cutting into your existing slab. Before you do any cutting, locate any existing utilities that may be installed in the slab. Once this is done you can plan the location of your catch basin as well as your drains. Note: Every municipality will have different regulations regarding the disposal of hazardous materials. Please always follow best practices and consult local rules and regulations when planning an automotive shop drain installation.

Planning and Cutting Concrete

Form should mirror functionality when choosing a layout for your Slot Drains. Catch basins should be accessible to employees and placed so that they can be easily connected to sewer lines or holding tanks. Slot Drains should be placed in areas where they will most effectively be able to collect water or other fluids that need to be drained from the shop floor. Keep in mind that your slot drains should terminate at a catch basin to enable retrieval of lost items and provide ease of access for maintenance.

Once you have determined where you want to place your drains you can mark the location on the floor and cut the concrete. Because a slot drain comes pre-sloped, and can be run the length of the shop, it requires less complex slopes than traditional point drains. Traditional drains require multiple angled planes to reach a central point. A slot drain only requires a minimum of two sloped planes. One on each side of the drain. The width of your drain slopes will determine the width of the cut you make in the concrete to install the slot drain. More slope will require a wider channel to be cut in the concrete. Global Drain Technologies recommends you cut an opening no less than 24” in width and that you use no less than a 0.5% slope.

Glass Lab Auto Glass chose to cut the smallest opening possible for their drain to avoid having to do extra concrete work. This creates a very small sloped area around the slot drain. The small slope matches this use case for the slot drain. They intend to wash the shop down daily and have their employees squeegee the water to the drain. A business with a different use case like a carwash or auto detailing center might want to have the slope extend further on all sides of the drain so that the water flows towards the drain with less human intervention.

Installing your Slot Drain

Prior to installing the Slot Drain rebar should be installed to reinforce the cut concrete slab. Next, install the catch basin and then connect the drain lengths in series. The Slot Drain System is pre-sloped, which means each section must be connected in the proper order. Ensure your drain is level using the integrated leveling points. When setting the height of your drain (and catch basin) be sure to take into account the thickness of your floor coating. If your floor coating is going to be ⅛” thick ensure your drain and basin are set to accommodate the thickness of your floor coating.

Secure your slot drain system to prevent it from floating during your concrete pour. Protect the opening of the Slot Drain with tape or protective film to prevent concrete from entering the drain. Once your Slot Drain System is secured, level, and protected you can pour your concrete. When pouring your concrete ensure that it completely encases the slot drain system and that there are no air pockets as this can affect the stability of the Slot Drain System.

For more detailed information on drain installation please consult our installation resources.

Slot Drain Installation with Concrete Flooring

Coating the Floor

Liquid Stone Floors used an epoxy floor coating with a flake finish. Their website describes this floor as “Highly customizable and so durable that your floor can take a beating.” Making it an ideal solution for an area that will have to stand up to the wear and tear of cars being driven and parked on it every day. This makes epoxy an ideal partner for the Slot Drain System in a light commercial automotive shop setting.

Liquid Stone Floors shared some tips and tricks with us.

-

Floor Preparation is extremely important. Grinding the concrete can help bring the floor into tolerances specified by the epoxy manufacturer as well as ensuring a clean surface to bond to.

-

Make sure the top of your Slot Drain System is properly covered with tape to ensure the drain is well protected. Having epoxy enter the drain can affect the future performance of the system and will need to be cleaned.

-

Epoxy installation is time sensitive so make sure you have everything prepared and accessible before you start.

-

Edge the epoxy coating after it dries to counteract drift. Some of your epoxy will drift onto the slot drain during the coating process. Liquid Stone Floors edged the drain with a grinder with a thin wheel (after the epoxy had set) to release the drain and make tape removal easier.

Pricing and Other Considerations

Global Drain Technologies original Slot Drain System is manufactured from T304 or T316 Stainless Steel load class rated and manufactured in North America to the highest industry standard. At the same time this system is built for installers. “It was as easy as Lego. And it was way easier than Ikea furniture. ,” says Guy, co-owner of Glass Lab Auto Glass.

The Slot Drain System is built for performance and beauty. Whether or not this is the right system for you will depend on a range of factors like: use case, aesthetics and budget. Below you can find some of our prebuilt kits that are available through our ecommerce store. However, if you are building a shop that must have custom designed drainage we can accommodate that as well. Our sales and engineering teams are ready to guide you through the process and make sure that your Slot Drain System fully meets all of your drainage needs. Contact us today to find out how.