Global Drain Technologies unveils the Alliance Partner Network to help accelerate modern drainage solutions for legacy plants in the food and beverage industry. Alliance Partner Network includes trusted EPC firms, general contractors, architects, engineers, and more.

Record profitability in the food and beverage segment has led to continuous capital investments. Chobani, Tyson, Smuckers, and others are expanding plants and seeking economies of scale and product innovation. The ground is shifting, and brands are looking to move fast.

To meet the moment, Global Drain Technologies officially announces the Alliance Partner Network of system integrators that accelerate new and legacy plant expansions by providing turnkey drainage solutions. The members of the Alliance Partner Network have been a trusted source of expertise for Global Drain Technologies customers for decades; offering drain evaluation services, whole-building projects, piping modifications, mechanical, plumbing, flooring scopes of work and new floor designs.

As brands run full-bore to seize innovation and improve throughput, plant managers and corporate VPs need trusted system integrators to deliver whole-building drainage solutions for legacy plants. The Alliance Partner Network offers design services, engineering, contracting, planning, scheduling, and more.

But corporate executives also need alignment on modern plant vision from trusted experts. “Services in the food and beverage segment have increased exponentially, and the introduction of Alliance Partner Network is a natural extension of relationships with customers,” says Viking Kristjansson, VP of Sales Engineering at Global Drain Technologies. “Brands need trusted experts for essential expansion projects.”

Book a consultation to find local lead contractors, and how they can lead a new facility project

Delivering on a Vision for Food Safety

As capital investment moves forward and the stakes get higher, corporate management needs a modern plant vision. New plants need to support rapid innovation and the ability to scale production volume. And, food safety challenges are not going away. The abundance of area drains and their underground piping for legacy plants prevents visibility into areas where pathogens can originate.

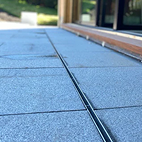

Essentially, food companies want to do more with less, and a whole-building approach to drainage solutions reduces staff resources while upholding food safety. Linear drain systems, such as slot and advanced trench drain systems, are designed to reduce the need for extensive underground piping, making drainage channels easier to access for cleaning and maintenance. The change in drain type also promotes easier cleaning and leads to improved standard operating procedures (SOPs).

“In general, our Alliance Partner Network recommends reducing underground piping to eliminate contamination sources,” says Kristjansson. “Eliminating area drains allows manufacturers to inspect and understand what’s happening in these areas.” Plant managers and operations at legacy plants call this “avoiding the 40-year-old problem” of excessive underground piping and floor slopes that cause continuous issues around drains, adds Kristjansson.

New plant projects are significant investments for food manufacturers. Through its ENVISION Services Global Drain Technologies works with brands to understand a project’s scope and specifies a local contractor within the Alliance Partner Network. Once selected, a lead general contractor collaborates with plant managers, operations, and the corporate VP to deliver on evaluation, product specification, planning, scheduling, and implementation.

For upgrades of legacy facilities, Global Drain Technologies RENEW offers a range of local contracting solutions through the Alliance Partner Network, including drain evaluation services, piping modifications, mechanical, plumbing, specialty, flooring scopes of work, new floor designs, drain recommendations and more. These turnkey solutions leverage the Alliance Partner Network, and its decades of experience in serving the food and beverage industry.

“Food processors have reached out to us due to our continuous relationship and track record with our drainage equipment and implementations,” says Kristjansson. “We connect them with the right local Alliance Partner for the work, and the lead contractor then holds the project with the brand.”

FoodSafe Drains Turnkey Services can accelerate project timelines, including custom drainage design and engineering solutions.